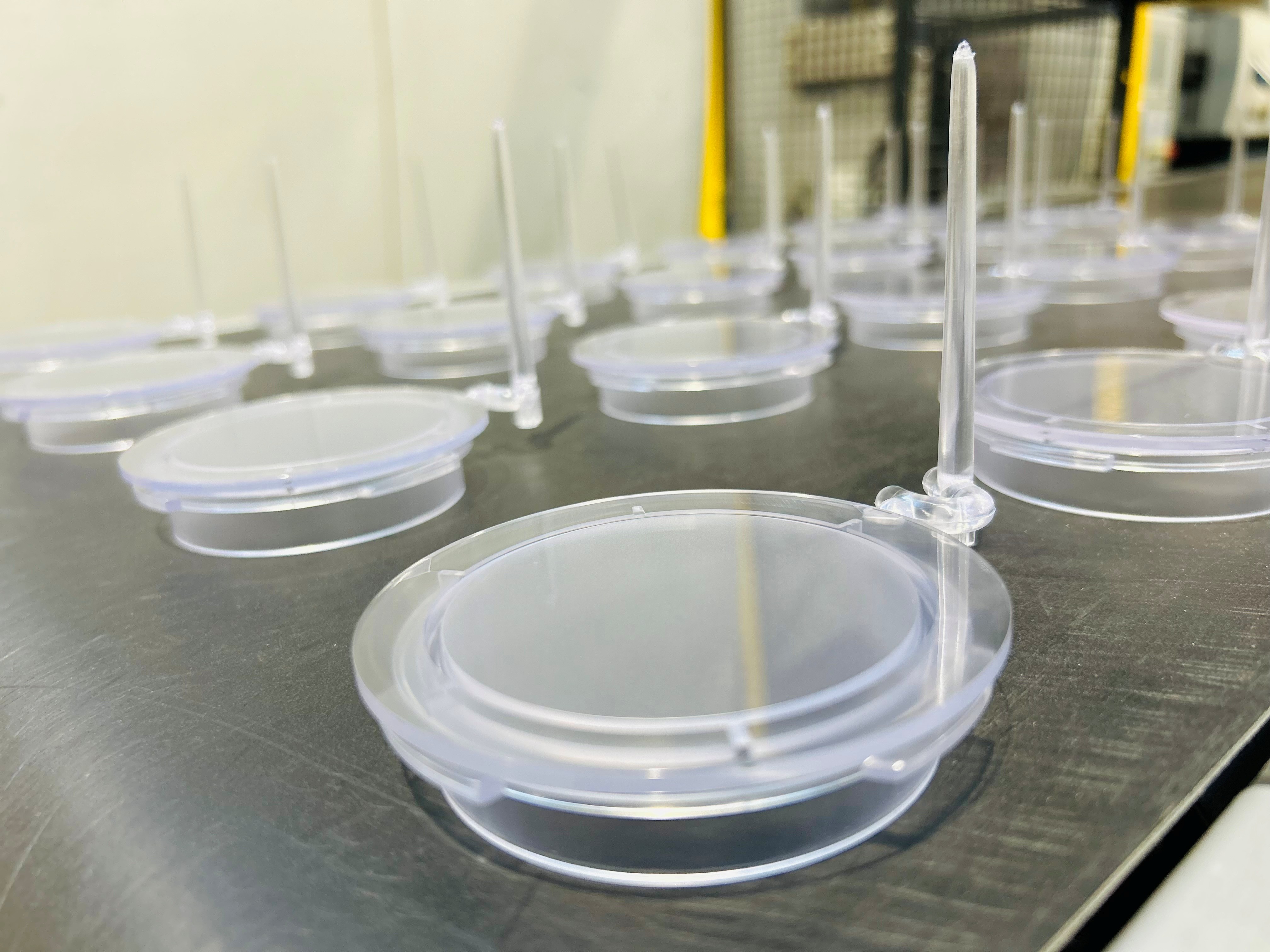

Thermoplastic injection moulding is a versatile manufacturing process designed for the efficient production of various plastic parts and components in large volumes. The process begins by feeding plastic pellets into a heated chamber via a hopper. In the chamber, the plastic melts and blends, then is injected under pressure into a mould. As the molten plastic fills the mould, it quickly cools and solidifies, taking the exact shape of the desired part. Once the part has cooled and hardened, the mould opens, and the finished component is ejected.

We offer shot weights ranging from 5g to 6kg with machines ranging from 100 to 650 tonnes clamp force. MTM’s facilities are geared up to cater for both low and high-volume production, by utilizing robotics and automated systems, we enhance efficiency, accelerate production, and minimize manual handling. This approach guarantees consistent cycle times and reduces the likelihood of defects.

MTM brings extensive experience in plastic injection moulding, partnering with businesses that require precise, dependable, and cost-effective components. Our expertise spans a wide range of industries, enabling us to assist with the development of complex product designs.

Thermoplastics we commonly use

| ABS | Acrylonitrile Butadiene Styrene |

| PPMA | Acrylic |

| HIPS | High Impact Polystyrene |

| HDPE | High-density Polyethylene |

| LDPE | Low-density Polyethylene |

| PA6 | Nylon 6 |

| PA66 | Nylon 66 |

| PA6+GF | Nylon 6 glass filled |

| PA66+GF | Nylon 66 glass filled |

| PBT | Polybutelene Terepthalate |

| PC | Polycarbonate |

| PC+ABS | Polycarbonate + Acrylonitrile Butadiene Styrene |

| PP | Polypropylene |

| PVC | Polyvinyl chloride |

| TPE | Thermoplastic Elastomer |

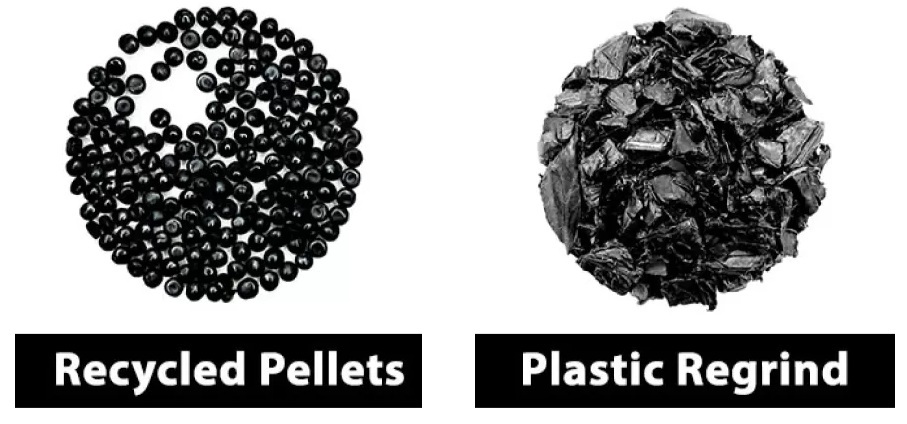

In addition to our prime grade materials, MTM also offers a wide range of Recycled and Hybrid polymer grades—each delivering several key benefits:

Using recycled materials in injection moulding not only helps preserve natural resources but also reduces production costs and environmental impact.

By offering recycled and hybrid options, MTM has helped many customers choose materials that lower both the cost of their end products and their carbon footprint.

Get in touch with us today to explore sustainable alternatives that suit your application and business goals