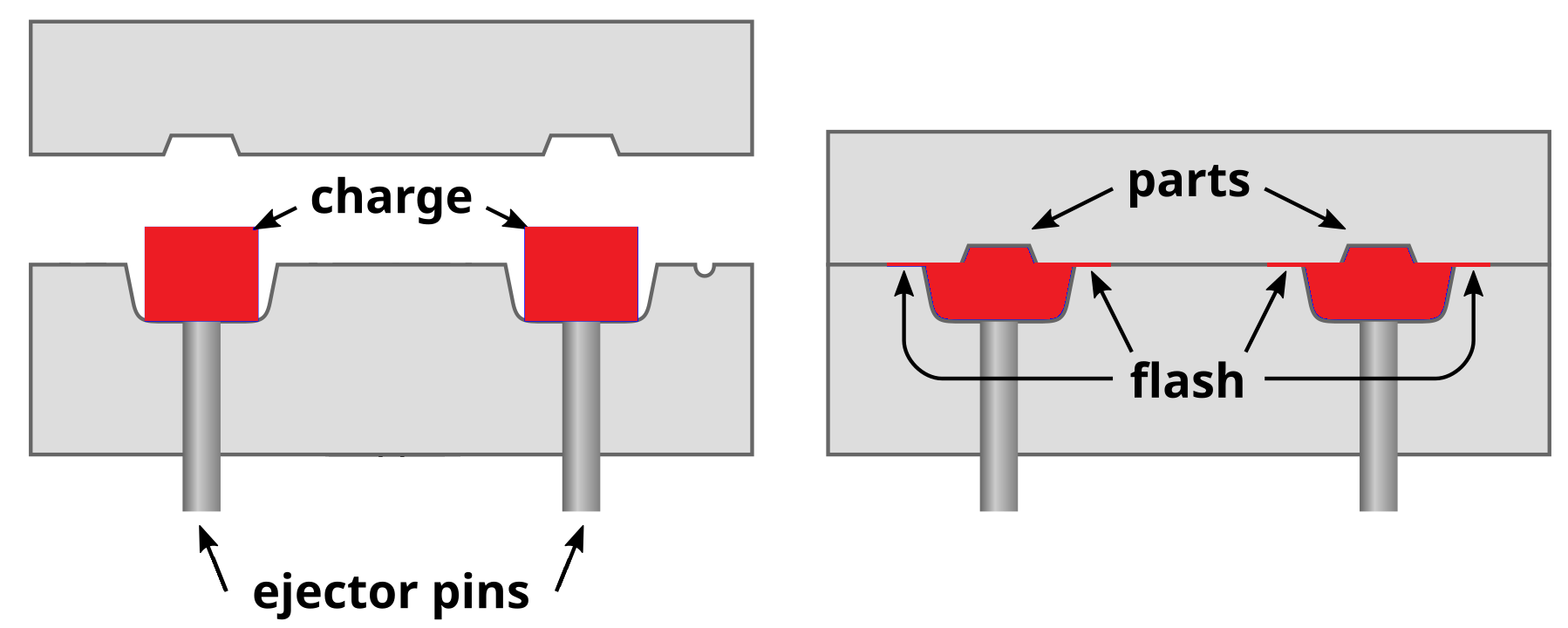

Thermoset Compression Moulding is a manufacturing process used to shape thermosetting plastics or composites. In this process, a pre-measured amount of material (often referred to as a charge) is placed directly into a heated mould cavity. The mould is then closed, and pressure is applied, causing the material to flow and fill the mould, conforming to its shape. Heat and pressure are maintained for a set period to allow the material to cure (harden). Once the curing process is complete, the mould is opened and the finished part(s) are ejected from the cavity.

MTM operates 40 compression moulding presses, ranging from 40 to 800 tonnes, with platen sizes up to 2 metres. We utilize a combination of steam and electrically heated platens, allowing us to accommodate a diverse range of tooling and manufacturing requirements.

Thermoset plastics we commonly use

| Vulcanized rubber | VR |

| Phenolic | PF |

| Polyurethane | PUR |

| Epoxy resin | TER |

| Polyester | UP |

| Melamine | MF |

MTM has many years’ experience in helping customers develop new applications, saving both time and money by replacing metal with composite materials.

MTM’s skilled project management team is able to offer all the necessary technical assistance required to ensure that the correct materials, and features are incorporated into the design of the product.

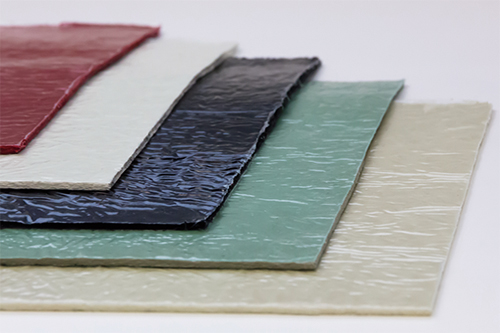

SMC is a polymeric composite material, which consists primarily of a thermosetting resin, mineral fillers, and a glass fibre or carbon fibre reinforcement. Additional ingredients such as catalysts, inhibitors, mould release agents, thickeners and colour pigments are used to enhance the performance and moulding process of the final product.

BMC is a polymeric composite material as above. It is just in a dough form.

Phenolic Moulding Compound (PF) is also commonly known as “Bakelite“ and is a thermosetting resin. It has excellent heat resistant properties and dimensional stability.